MUMBAI: The urgency to create multiple quarantine spaces in the city has prompted innovative ideas to furnish these halls.

See MoreVision

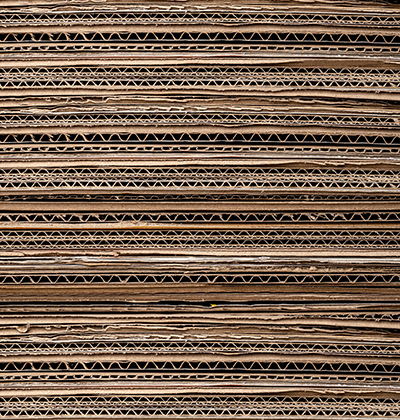

To be amongst the most efficient & environmentally friendly paper & packaging companies globally.

It is of utmost importance to us. We shall always endeavour to engage in environmentally congenial practices.

Economy of operation is imperative. Wealth generation is the key to well being of people. We shall ensure efficiency of operations and continuously enhance value addition.

This shall be the source of continuous improvement of our people. Training & learning shall be the means of adding value to our people.

Entrepreneurship shall be the spirit of our organization, where every colleague shall be a responsible leader with freedom of thought & action.

Excellence & being the best at whatever we do will be the measure of success of our people, products, processes, plants & projects.

Aarya bhavna, Karya Sadhana.